MODBUS PLC Delta DVP and SINEE A90 inverter

1. Overview of MODBUS PLC Delta DVP

- See more :

- Modbus RTU protocol is an open protocol, using RS-232 or RS485 physical transmission and Master-Slave model. This is a protocol that is widely used in many fields such as BMS (Building Management Systems), automation, industry, electricity, …. Surely you will wonder, why this Modbus protocol It’s so popular, where to go, what device to touch, almost all have this protocol? Well, the answer to the above question can only be summed up in a few words: Stable – Simple – Easy to use.

- Modbus is considered as a communication protocol operating at the “Application” layer, providing Master/Slave communication between devices connected via buses or networks. On the OSI model, Modbus is located at layer 7. Modbus is defined as a “question/answer” protocol and uses the corresponding “function codes” for questioning.

2. MODBUS PLC Delta DVP message structure

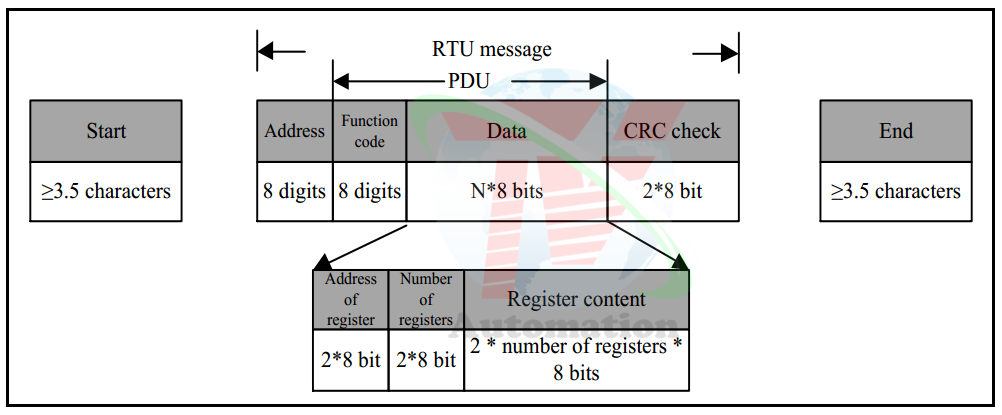

- A Modbus RTU message consists of: 1 address byte – 1 function code byte – n data bytes – 2 CRC bytes as shown below:

- Address byte: determines which device bear the address to receive data (for Slave) or data from which address(for Master). This address is specified from 0 – 254

- Function code byte: specified from the Master, identifying the data request from the Slave device. Code example 01: read bit stored data, 03: read byte instantaneous data, 06: write byte data to slave, 15: write multi-bit data to slave

- Data Bytes: Identifies the data exchanged between Master and Slave

- Bytes CRC: 2 bytes of transfer function error checking. how to calculate the value of Byte CRC 16 Bits

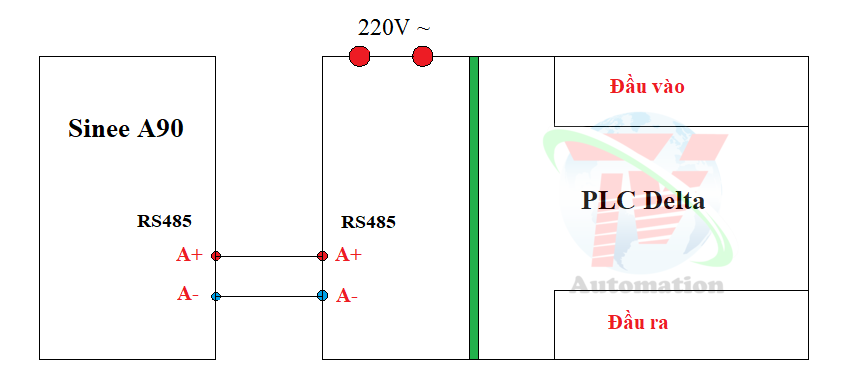

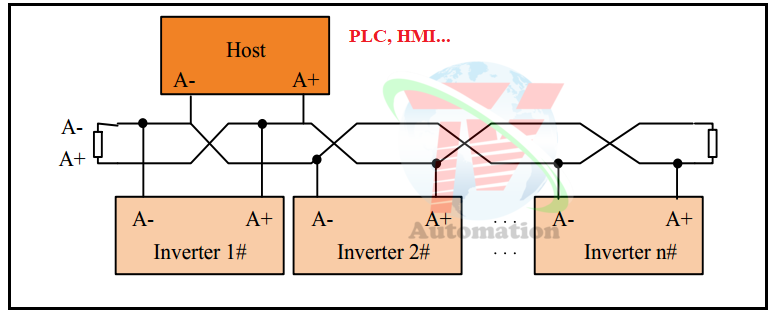

3. Communication hardware connection

- Depending on the device, there are different communication pins, in this case Sinee A90 inverter is A+, A-

- In some devices it can be RS485+, RS485-, or D+, D-…

- According to the diagram, we connect the A+ pin of the Delta PLC to the A+ of the inverter and correspond to the A- pin.

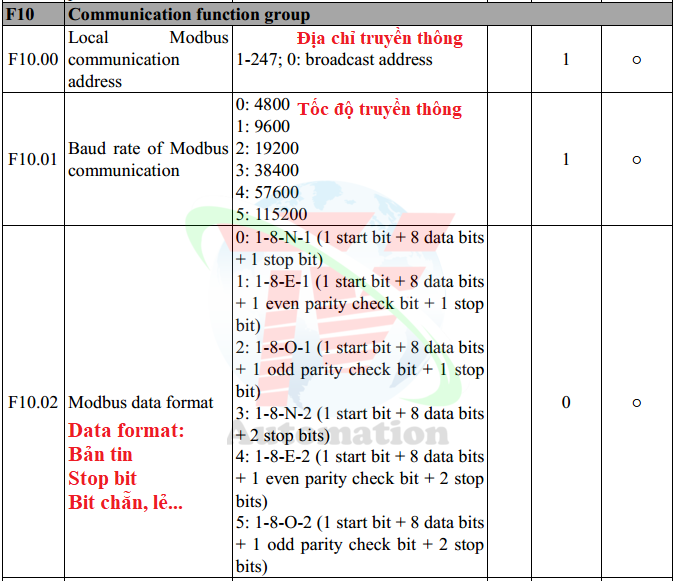

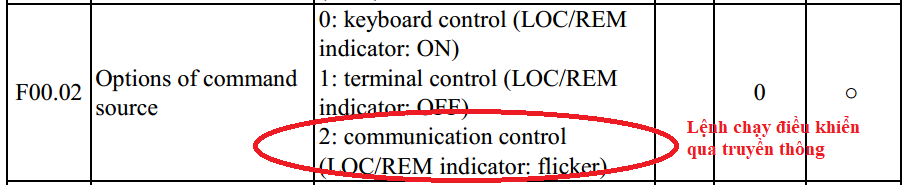

4. Sinee A90 inverter parameter setting

- Running command setting via Sinee A90 inverter communication

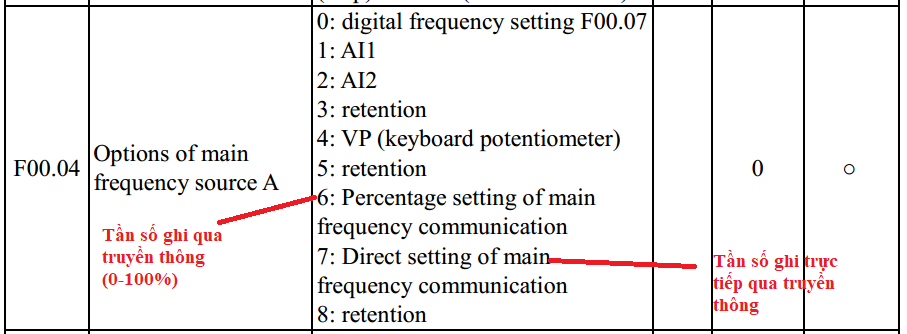

- Frequency source setting via communication

- Sinee A90 multi-inverter communication connection diagram

5. Communication setting in PLC Delta

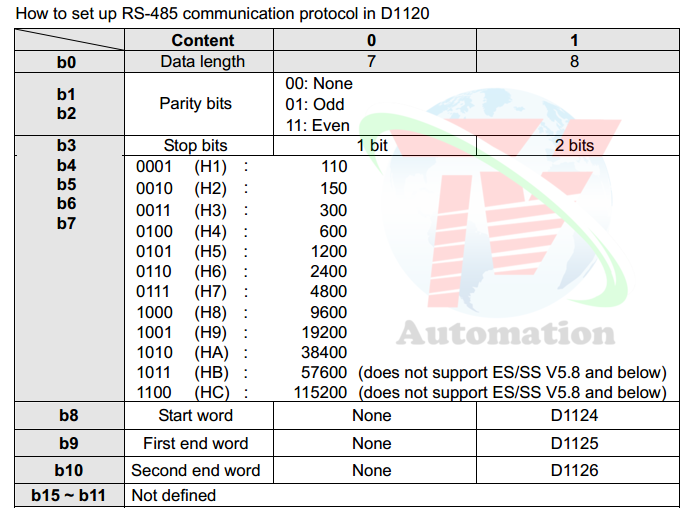

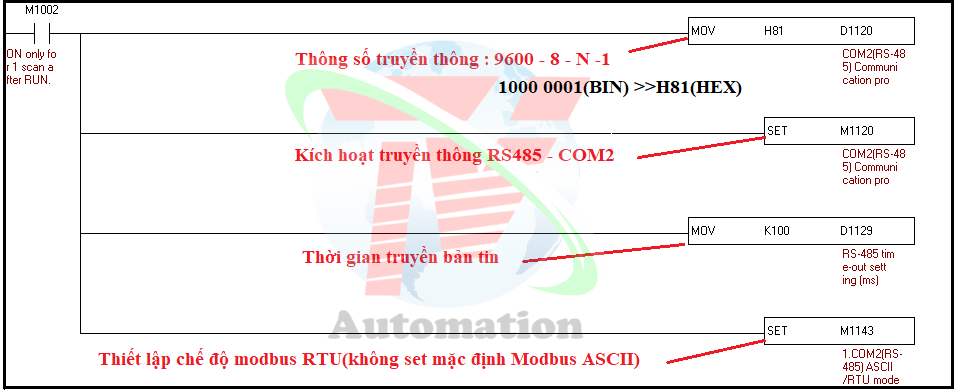

- Set communication parameters PLC Delta

- In this article we choose the setting parameters: 9600 – 8 – N – 1

- Set communication parameters in PLC Delta

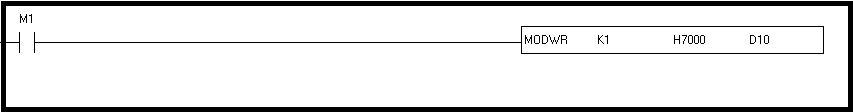

- Command to write run command parameter in PLC Delta to write run command for Sinee A90 inverter

- K1 : Address of Sinee A90 . inverter

- H7000 : Address of Sinee A90 inverter running instruction register

- D10 : Memory cell to write the value

- H001 : Run forward

- H002 : Reverse running

- H005 : Stop deceleration

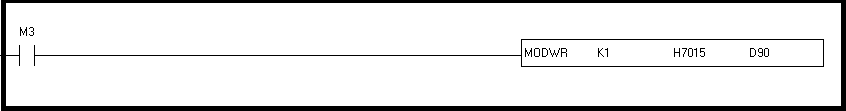

- Command to write frequency parameter in PLC Delta to write run command for Sinee A90 inverter

- H7015 : Frequency register address of the inverter

- D90 : Frequency value register

- Link program reference PLC Delta DVP-14SS2 and inverter Sinee A90:

6. Contact

MODBUS PLC Delta DVP and SINEE A90 inverter

- If you have a need to buy or quote automation equipment or need further advice, please contact us immediately for dedicated, fast and effective support!

- TRI VIET AUTOMATION SOLUTION JOINT STOCK COMPANY

Ho Chi Minh Address: 36/6 street 4, quarter 5, An Lac A ward, Binh Tan district, Ho Chi Minh city.

Hanoi Address: 41/M2, Yen Hoa new urban area, Yen Hoa ward, Cau Giay district, Hanoi city

Phone: 0984868617

Email: trivietautomation.info@gmail.com

MST: 0316876097

Website: www.triviettech.com.vn – www.sineedrive.vn

Working hours: Monday – Sunday / 7:30 AM – 5:00 PM