Can inverter replace servo driver?

1. Can the inverter replace the servo driver?

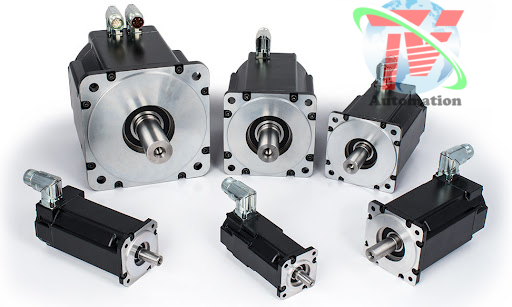

- Currently, the demand for using servos is increasing and gradually becoming popular in machine systems. However, there are many cases where the servo drive fails while the servo motor is still working fine. Users cannot buy a replacement drive for many objective reasons. At this time, having to replace the entire servo system is something that no business wants because the cost is very high.

- So to save costs, can inverters be used instead of servo drives to control servo motors?

2. Problem Analysis

- Using inverters to replace damaged servo drives to save costs is a solution chosen by many business owners. However, there are only a few high-end multi-function inverters on the market. Integrate special features. Can help control servo motor speed for business when servo drive fails. (The manufacturer does not have a replacement or the old drive line has been discontinued).

- In terms of structure, servo motor is a PM synchronous motor. With rotor (made with permanent magnet). And works by closed loop feedback system. When the motor is running, the rotor speed and angle will be continuously fed back from the encoder to the control circuit on the servo driver. It is possible to adjust the speed of the motor, the rotation speed of the magnetic field to best synchronize with the rotor. So when you want to control the servo motor. The key point is to choose a controller with closed loop feedback.

- Meanwhile, the most common type of inverter is the open-loop inverter with 3-phase asynchronous motor. So when using this type of inverter instead of a servo drive and attached to a servo motor, the following cases will occur:

- The servo motor operates with loud noises, jerks and vibrations.

- If the frequency is gradually increased, the servo motor will heat up and the inverter will report overcurrent.

- In case of running, the force of the motor is also weak and it is almost impossible to carry the load.

2.1. Technical requirements

- Therefore, to be able to use the inverter instead of the servo drive to control the servo motor. The following requirements must be complied with:

- The inverter has advanced closed-loop feedback control with a dedicated vector algorithm for PM series motors.

- The inverter receives the signal from the Controller and reads the encoder signal of the servo system.

- In fact, if you choose the right type of inverter to replace the servo drive, it will not affect the control ability as well as the operation of the servo motor or the mechanical system.

- SINEE EM600 high-end closed-loop inverter, precise control. For all types of AM and PM motors, support pulse encoder signal. At the same time, it integrates special control functions such as position, torque, speed, etc. to ensure extremely fast acceleration, high accuracy…

- SIEE EM600 is a multifunctional intelligent super inverter with world leading vector control technology. Can control many different types of motors with high efficiency. The inverter can meet the majority of customers’ basic customization needs in the production process and reduce the installation and replacement costs of new equipment.

3. Notes on installation

- Here are the notes when using the inverter instead of the servo driver. To control the servo motor that you need to know to make the most appropriate choice:

- Adjust the parameters of the inverter in accordance with the parameters of the servo motor.

- It is necessary to pay attention to the voltage of the servo motor to set and limit the voltage on the inverter to match the voltage of the motor.

- Select the capacity of the inverter to match the capacity of the servo motor.

- Read carefully the process and carefully read the installation and operation instructions of the manufacturer before using.

4. Contact

Can inverter replace servo driver?

- If you have a need to buy or quote automation equipment or need further advice, please contact us immediately for dedicated, fast and effective support!

- TRI VIET AUTOMATION SOLUTION JOINT STOCK COMPANY

Ho Chi Minh Address: 36/6 street 4, quarter 5, An Lac A ward, Binh Tan district, Ho Chi Minh city.

Hanoi Address: 41/M2, Yen Hoa new urban area, Yen Hoa ward, Cau Giay district, Hanoi city

Phone: 0984868617

Email: trivietautomation.info@gmail.com

MST: 0316876097

Website: www.triviettech.com.vn – www.sineedrive.vn

Working hours: Monday – Sunday / 7:30 AM – 5:00 PM